Water tanks require regular maintenance to preserve the integrity of the structure and protect the community’s investment. This case study investigates the true costs of short vs. long term asset management and how to extend a water tank’s expected life.

Prior to creating a plan, it is crucial to identify a system’s assets, risks, and goals, and how that can affect a community’s financial investments in its water storage tanks.

A community’s water infrastructure has many assets, from their water treatment plant to their water storage tanks. Once each asset has been identified, it is important to have them evaluated by a qualified inspection firm to determine the life expectancy, as well as their coatings lives. Once the evaluation is complete, the findings are handed over to an engineering team who puts together a written report detailing their recommendations. This should include an estimate of how long the current coatings will protect the structure and substrate. The decision to repair, recondition or replace an asset should be determined based on the current conditions of the asset, life expectancy, and current costs.

Many communities choose a plan that encompasses many short-term fixes instead of a long-term solution. While these smaller numbers may look more appealing at first, this will often end up costing the owner substantially more in the long run.

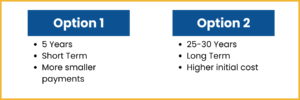

For instance, if a municipality needs to recondition their tank, they may be presented with two options:

At first glance, Option 2 may present “sticker shock” while Option 1 may seem more affordable, but this is looking at it from a short-term standpoint. Plans like Option 1 are typically based off of minor repairs and overcoating the tank, while Option 2 is based off of bringing it up to code (AWWA, OSHA, state regulations, etc.), maintenance upgrades, structural repairs, and a full reconditioning. However, after that initial five-year period, the city may need to recoat/repair the tank again, whereas the second option would not require major maintenance for many years to come.

Over the course of 25-30 years, Option 1 may end up costing substantially more than Option 2’s upfront cost. By planning long-term, a city can save upwards of millions of dollars over the service life of their water tank. This is based on a life expectancy of a 100 years, but this can vary depending on the tank size.

Each asset and its life cycle is unique and will have its own solution, which is why it is important to look at the bigger picture. Assets will be prioritized with cost estimates that can be included in their CIP. At KLM Engineering, we believe in finding a solution that saves communities money in the long run. We are committed to maximizing the longevity of each asset. Contact us to see how we can do the same for community by calling 651-773-5111 today.